|

| Polyphosphate fluid fertilizer |

Phosphorus deficiency limits the growth and

productivity of plants in many parts of the world. Since many soils are low in

P, this nutrient is commonly added to improve crop yield and quality.

Phosphorus is derived from geologic deposits distributed across the globe.

Polyphosphate is an excellent liquid fertilizer that is widely used in

agriculture.

Production

Phosphoric acid is the starting material for most commercial phosphate

fertilizers. However, the acidity and some of the chemical properties make

this material difficult to use directly. When phosphoric acid and ammonia are

reacted, water is driven off and individual phosphate molecules begin to link

together to form a “polyphosphate” fluid fertilizer.

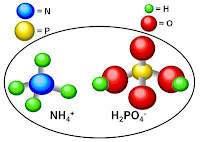

A single phosphate molecule is called orthophosphate. “Poly” refers to

multiple phosphate molecules linked in a chain. Each linkage of phosphate

molecules has a name depending on its length, although polyphosphate is the

general term that includes all of these linked molecules.

The most common ammonium polyphosphate

fertilizers have N-P2O5-K2O

composition of 10-34-0 or 11-37-0. Polyphosphate fertilizers offer the

advantage of a high nutrient content in a clear, crystal-free fluid that is

stable under a wide temperature range and has a long storage life. A variety of

other nutrients mix well with polyphosphate fertilizers, making them an

excellent carrier for micronutrients that may be needed by plants.

|

| "Poly" in polyphosphate refers to chains of phosphate... short or long |

Chemical Properties

Agricultural Use

In polyphosphate fertilizer,

between half and three-quarters of the P is present in chained polymers. The

remaining P (orthophosphate) is immediately available for plant uptake. The

polymer phosphate chains are primarily broken down to the simple phosphate

molecules by enzymes produced by soil microorganisms and plant roots. Some of

the polyphosphate will decompose without the enzymes. The enzyme activity is

faster in moist, warm soils. Typically, half of the polyphosphate compounds are

converted to orthophosphate within a week or two. Under cool and dry

conditions, the conversion may take longer.

Since polyphosphate

fertilizers contain a combination of both orthophosphate and polyphosphate, plants

are able to use this fertilizer source very effectively. Most P-containing

fluid fertilizers have ammonium polyphosphate in them. Fluid fertilizers are

commonly used in production agriculture, but not widely used by homeowners.

Fluids are convenient for farmers since they can be easily blended with many

other nutrients and chemicals and each drop of fluid is exactly the same. For

most situations, the decision to use dry or fluid fertilizers is based on the

price of nutrients, fertilizer-handling preferences, and field practices rather

than significant agronomic differences.

Management

Practices

Ammonium polyphosphate is

primarily used as a source of P nutrition for plants. Since P has limited

mobility in most soils, efforts should be made to place the material as close

to developing roots as practical. Practices should be adopted to minimize the

movement of P from the soil into adjacent water. Excess P in surface water can

stimulate the growth of undesirable algae.

Non-agricultural

Use

Phosphate is an essential

component in human nutrition. Polyphosphate is an approved additive for food

and requires no special precautions in handling. Polyphosphate compounds are

widely used as a flame retardant on many products, including wood, paper,

fabric, and plastic. It is also used as a commercial retardant for forest

fires. The mode of action involves the ammonium polyphosphate forming a charred

layer after burning, thereby preventing further flames.

Read the fact sheet on some of the important properties of polyphosphate and how it is used.

http://tinyurl.com/polyphosphate